Keyword: insect light trap, UV-A lamp, Curtron BL400, PestWest, adhesive insect trap, electric grid insect killer, food factory fly trap, China sourcing agent, Sourcingate

Word Count: ~2500

🪰 Introduction: Why Industrial Insect Light Traps Matter for Food Factories

When it comes to maintaining hygiene and pest control in food production environments, few devices are as crucial as industrial insect light traps. These systems ensure that no flying insects—mosquitoes, flies, or moths—can contaminate sensitive areas like bottling lines, packaging zones, and kitchens.

Recently, our sourcing team at Sourcingate.com was commissioned by PepsiCo’s food factory to find the most reliable insect light traps suitable for large-scale industrial use. The client specifically required adhesive-type UV-A traps, compliant with FDA and HACCP standards, to ensure absolute cleanliness and avoid the risk of insect fragments contaminating production areas.

Before identifying the right factory and model, we conducted a detailed technical and brand comparison between two major international manufacturers — Curtron (USA) and PestWest (UK) — both leaders in professional food industry pest control.

But before diving into brand comparisons, let’s clarify the fundamentals: there are two main types of insect light traps in the market, and understanding their differences is the first step to making a smart sourcing decision.

⚡ Type 1: Electric Grid Insect Killer (High-Voltage Type)

Working Principle:

The electric grid insect killer uses UV-A lamps to attract insects and a high-voltage metal grid (around 2000–2500V) to kill them instantly upon contact. The high voltage is produced by an internal transformer that steps up normal 220V power to several thousand volts.

Features:

- Immediate results: Flies and mosquitoes die instantly when they touch the grid.

- Wide coverage: High power lamps (usually 2×40W = 80W) cover large open areas.

- Durable structure: Typically made of aluminum or stainless steel for outdoor and warehouse use.

Limitations:

- Not suitable for food factories. The electric discharge may scatter insect fragments into the air.

- Audible “zap” noise when killing insects, which can be disturbing in quiet environments.

- Requires regular cleaning to remove dead insects from the tray and grid.

- Higher energy consumption due to the high-voltage circuit.

Ideal for:

Warehouses, garbage zones, farms, or outdoor perimeters where hygiene requirements are moderate but efficiency and large coverage are needed.

🧲 Type 2: Adhesive Glue Board Insect Light Trap (Food Factory Standard)

Working Principle:

This model also uses UV-A light (365 nm) to attract insects, but instead of killing them with electricity, it captures them silently on a sticky glue board placed behind the light source. The glue board is replaced periodically, ensuring that insects are trapped cleanly and hygienically.

Features:

- 100% Silent operation – perfect for kitchens, food lines, or hospitals.

- No electric grid, no sparks, no contamination risk.

- Meets international hygiene standards (HACCP, FDA, CE, RoHS).

- Easy maintenance: Simply replace the glue board every 30–45 days.

- Stable, low power consumption: Usually 2×15W or 2×18W UV-A tubes.

Ideal for:

Food and beverage factories, restaurants, cleanrooms, pharmaceutical labs, and any place where sanitary pest control is essential.

🔧 Technical Comparison: Electric Grid vs Adhesive Type

| Specification | Electric Grid Type | Adhesive Glue Board Type |

|---|---|---|

| Voltage System | 2000–2500V high-voltage electric grid | 100–240V AC (no high-voltage circuit) |

| Killing Method | Instant electrocution | Sticky glue board trapping |

| Sound | Audible “zap” | Completely silent |

| Safety | Moderate (risk of electric shock) | High (no electricity on surface) |

| Cleanliness | May scatter insect remains | Hygienic and compliant with food standards |

| Maintenance | Clean grid regularly | Replace glue board |

| Power Consumption | Higher (30–80W + transformer loss) | Lower (30–50W) |

| Typical Coverage | 300–500 m² | 100–350 m² depending on lamp power |

| Certifications | CE / EMC | CE / RoHS / HACCP / FDA |

| Best Use | Outdoor, warehouses | Food factories, kitchens, hospitals |

✅ Conclusion:

If your project involves food or beverage manufacturing, the adhesive glue-board type is the only choice accepted under HACCP and FDA standards — and this was exactly the requirement from PepsiCo when they commissioned us.

🧠 Our Brand Benchmark: Curtron vs PestWest

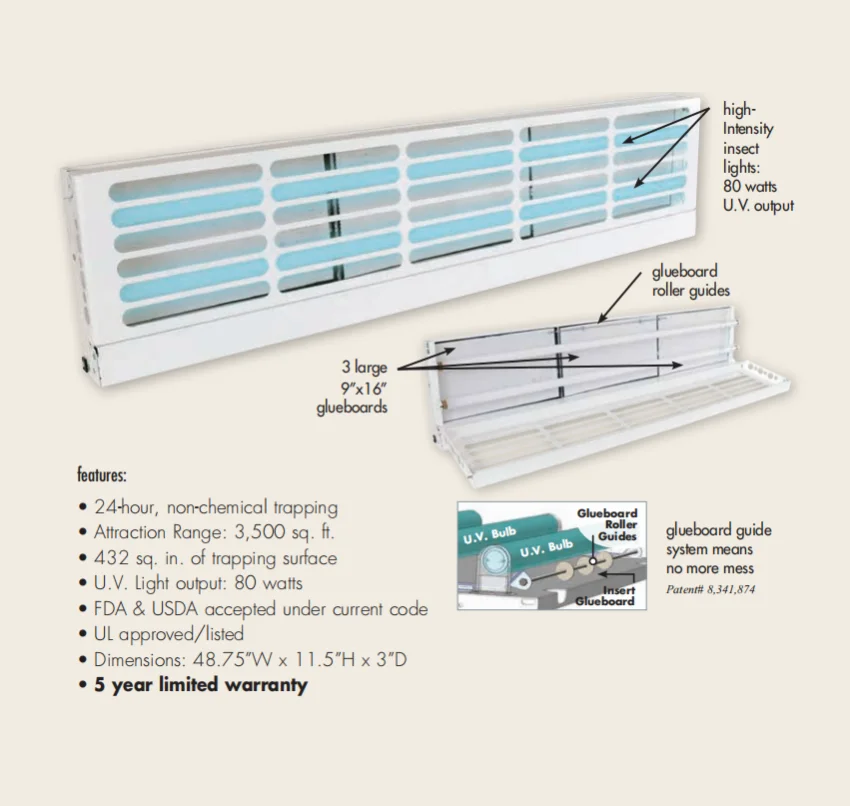

To ensure we sourced the most suitable and cost-effective models, our team conducted a full benchmark between Curtron BL400 Pest-Pro Series 400 and PestWest Chameleon 2×2, two of the most recognized adhesive insect traps used in global food facilities.

| Parameter | Curtron BL400 Pest-Pro 400 (USA) | PestWest Chameleon 2×2 (UK) |

|---|---|---|

| Size | 49” × 11.75” × 3.5” (124.5×29.8×8.9 cm) | 47” × 12” × 3.5” |

| Power | 80 W total (2 × 40W UV-A lamps) | 60 W total (2 × 30W UV-A lamps) |

| Coverage Area | 3,500 sq ft ≈ 325 m² | 3,000 sq ft ≈ 280 m² |

| Lamp Type | UV-A Actinic Lamp (365 nm) | UV-A Actinic Lamp (365 nm) |

| Typical Lamp Brand | PHILIPS TL-D 15W/10 or OEM | Osram / Philips UV-A |

| Trapping Method | 16” × 9” replaceable glue boards | Large multi-layer glue boards |

| Housing Material | Powder-coated metal | Stainless steel or aluminum |

| Certifications | UL Listed | CE / RoHS / HACCP |

| Ideal Use | Food factories, warehouses | Commercial kitchens, bakeries, retail food areas |

Both models meet professional food safety standards and operate silently with stable UV-A output at 365 nm, the optimal wavelength for attracting flying insects.

🏭 Finding the Right Factory in China

After studying these global brands, our sourcing team identified several Chinese manufacturers capable of producing OEM or ODM adhesive insect light traps that meet or even exceed Curtron and PestWest standards.

Our evaluation included:

- Material inspection: Metal housing vs ABS options, safety, and durability.

- Lamp performance testing: 365 nm UV-A output, luminous decay, temperature stability.

- Certifications verification: CE, RoHS, EMC, and optional HACCP compliance.

- Sample quality check: Adhesive strength of glue boards, ease of maintenance, and build precision.

- Voltage adaptation: Ensuring models can work at AC 220V/50Hz for Middle East and Asia, or AC 110V/60Hz for US markets.

Through our technical team’s inspection, we selected a factory partner with full in-house UV lamp production and metal housing fabrication, ensuring:

- consistent lamp wavelength (365 nm ± 5 nm)

- shatterproof coating for food safety

- IPX4 water protection

- and export-ready documentation for UL or CE certification.

🌿 Why PepsiCo Chose the Adhesive Type

For multinational food companies like PepsiCo, hygiene control is not just about pest removal — it’s about preventing contamination entirely. The adhesive insect trap meets these key criteria:

- Silent operation — essential for clean, quiet production areas.

- No electric sparks — eliminates risk of insect debris flying.

- Shatterproof UV lamps — prevents glass fragments in case of breakage.

- Replaceable glue boards — easy maintenance without shutting down the line.

- Compliance with food safety audits — CE, RoHS, HACCP ready.

After confirming these standards, we finalized a model matching Curtron BL400’s 80W UV-A output, with a stainless steel housing, replaceable glue boards, and Philips TL-D 15W/10 Actinic BL lamps as an optional upgrade. This configuration ensures optimal insect attraction at 365 nm, full HACCP compliance, and easy integration into PepsiCo’s existing food production system. By combining high UV-A efficiency with hygienic adhesive capture, the solution provides continuous, contamination-free insect control suitable for large-scale manufacturing environments.

📞 Contact us:

Website: https://sourcingate.com/

WhatsApp: +86 15258090639

Email: mimi@sourcingate.com